Reliability

Reliability is the key word!

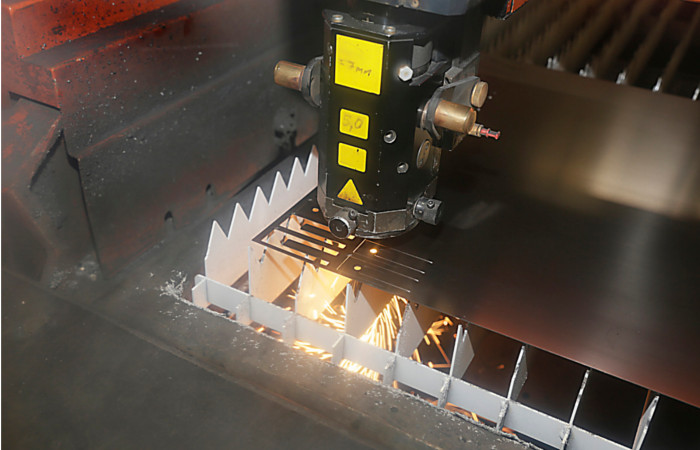

At THY WindPower we know that service costs. Therefore, we have designed our small wind turbines as simple and as durable as possible. This means that the amount of components is reduced, reducing therefore the possibility of a breakdown.

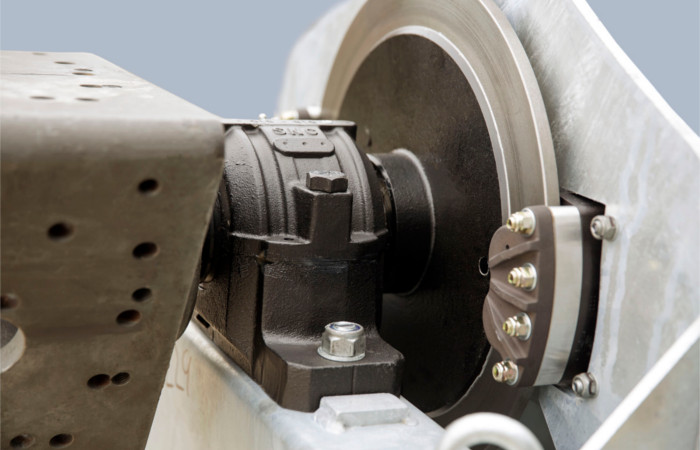

Our products are dimensioned with a minimum safety factor of 3.0, which means that the turbines of 6 kW are equipped with a 18 kW gearbox and the 10 kW models with one of 35 kW. A large safety factor reduces the load on the gearbox, which is operating at only 1/3 of its capacity. Lifetime of the components is therefore increased, meaning that the gearboxes will last as long as the turbine will operate.

As every machinery, also our products require maintenance, but in very limited amounts. Furthermore, being all standard industrial components, it is very easy and cheap to find spare parts.

We would like to service your THYWP turbine, but as the rotor diameter of the turbine is less than 40m2, there is no legal requirement that it is serviced by a certified/authorized service company. You can do it yourself - or get help from your local auto mechanic. Please, note that protection equipment (approx. 1,000 DKK) and a working-at-heights training course (approx. 1,000 DKK) are required to be able to climb the wind turbine.

The wind turbine is sold with a comprehensive service manual, which can be used for the maintenance. Please note that other wind turbine manufacturers require service agreements of 5-10,000 DKK - or more per year. This means that service costs are equivalent to 15 - 25% of the turbine's annual turnover.

The small wind turbine is not laid down for service. We believe that a turbine is set up for standing, which is also the case for larger wind turbines - Vestas and Siemens do not put their turbines down for service! When servicing, you can just use the ladder on the side of the wind turbine and the safety wire present. From the basket on top of the wind turbine all parts can be reached.

If a fault occurs and a component has to be replaced, we have developed a man-made lightweight crane that can be attached to the turbine and can lift all parts. Additionally, the turbine can be started while working on it, so that the troubleshooting process can be easier. Collapsible wind turbines can not be started when they are on the ground, making it more difficult to detect problems.